chiller Coating services

chiller Coating

Preserve Performance, Prevent Corrosion

At BMI Mechanical, we know your chillers are at the heart of your facility’s cooling system. Corrosive damage to chiller components—especially tube sheets and end bells—can lead to costly breakdowns or even a complete cooling system shutdown. Our specialty chiller coating services are designed to stop corrosion in its tracks and keep your systems running reliably.

The danger of Galvanic Corrosion in Chillers

Many chillers use copper tubes inserted into carbon steel tube sheets. This combination of dissimilar metals creates a perfect scenario for galvanic corrosion. Over time, the carbon steel begins to deteriorate, leading to:

Reduced water flow and cooling efficiency

Sediment build-up and clogging

Tube sheet perforation

Loss of refrigerant

Risk of unplanned downtime or catastrophic system failure

Left untreated, these issues can dramatically shorten the lifespan of your chiller and result in expensive emergency repairs or equipment replacement.

BMI’s Advanced Epoxy Chiller Coating solution

We help you avoid these problems with our proven, long-lasting chiller coating process:

Surface Preparation:

We begin by bead-blasting all coating surfaces to a near white metal profile, ensuring optimal adhesion and a clean foundation for the coating system.Corrosion Repair:

Any areas of corrosion or deterioration are expertly repaired to restore structural integrity and prepare the surface for coating.Epoxy Coating Application:

We apply a premium 100% epoxy solution in a three-coat system, with each coat applied at 10–15 mils for maximum durability and protection. This creates a seamless, waterproof barrier that isolates dissimilar metals, prevents further corrosion, and extends the service life of your chiller.

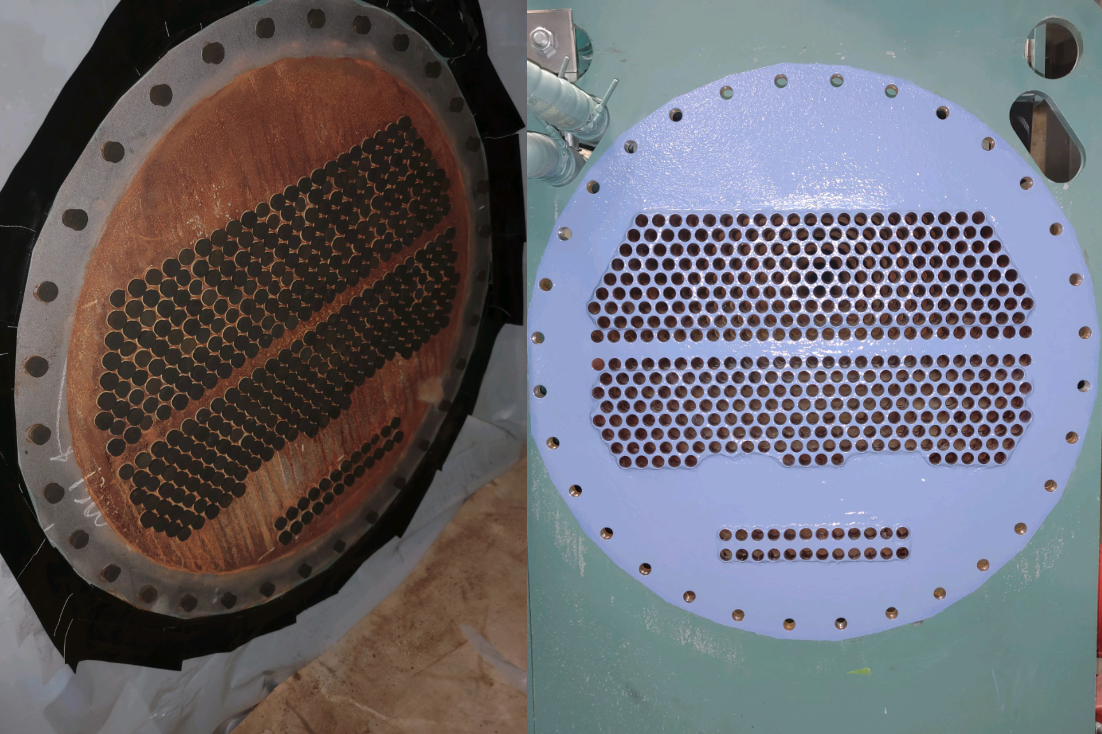

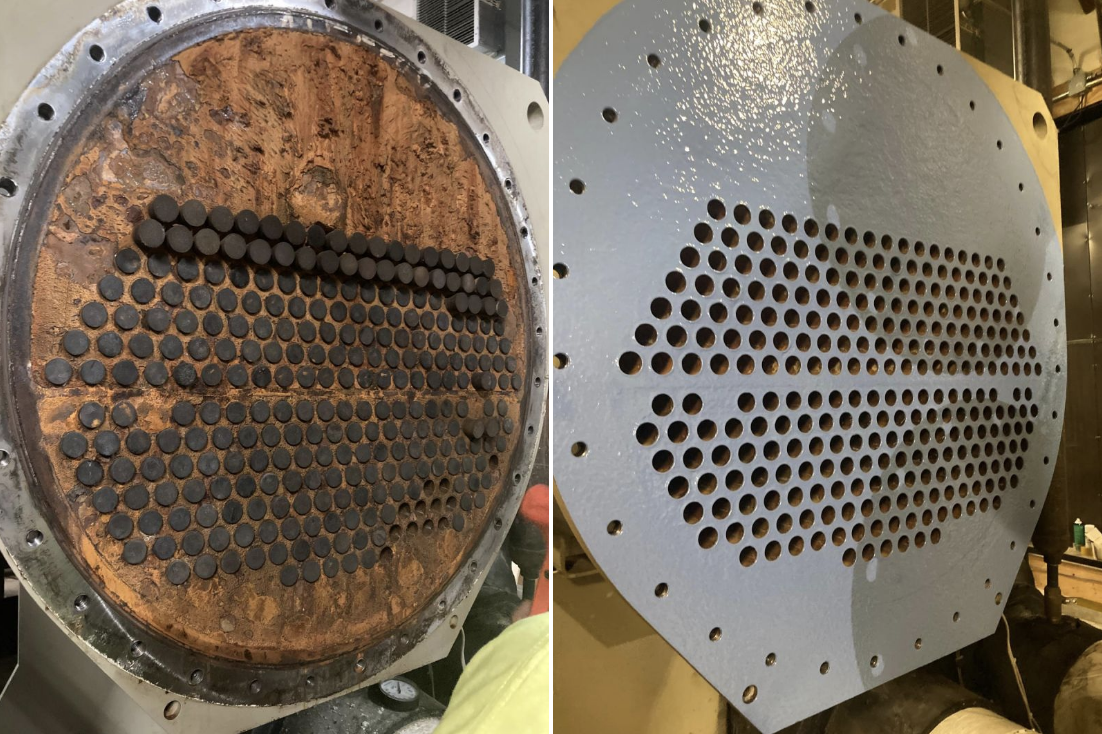

BEfore & After Photos

Reliable, Efficient, and Easy-to-Maintain Chillers

From rusty and clogged to renewed and protected, your chiller is returned to service with:

Improved cooling performance and energy efficiency

Reduced risk of leaks, corrosion, and refrigerant loss

Noticeably easier and faster cleaning times

Lower maintenance and repair costs

Peace of mind knowing your critical equipment is protected

Why Choose BMI Mechanical?

Long before we became New England’s trusted specialty coating and pump/motor specialists, we learned the value of showing up, listening closely, and delivering more than promised. Our team combines decades of hands-on experience with a solutions-driven, customer-first approach—delivering exceptional service to organizations across New England, especially the Greater Boston area.

With BMI, you get direct access to knowledgeable professionals, clear communication, and a hardworking crew focused on building long-term partnerships. We’re as committed to your facility’s success as you are.

Ready to protect your chiller and avoid costly breakdowns?

Contact BMI Mechanical today to schedule a chiller coating consultation or learn more about how our specialty coatings can safeguard your facility’s most important systems at 603-394-2188 or email us.