cooling tower Coating

cooling tower coating

Protect Your Facility’s Most Valuable Cooling Asset

Cooling towers are among the most critical—and costly—machines in your facility. Without proper maintenance and protection, they can quickly become a source of water loss, inefficiency, and expensive repairs or replacements. At BMI Mechanical Inc., we deliver expert cooling tower coating and repair solutions that extend the life of your equipment and help you avoid unnecessary capital expenditures.

preventing Corrosion & Water Loss in Galvenized and Stainless Steele Towers

Cooling towers and related components—such as package towers, chilled water tanks, collection basins, field-erected towers, ice storage tanks, and more—are constantly exposed to harsh chemicals and environmental elements. Over time, this exposure leads to:

Corrosion of galvanized metals

Degradation of rubber seams in stainless steel towers

Water leaks and water damage

Reduced operational efficiency

Increased risk of costly downtime or replacement

Unchecked, these issues can spiral into major facility headaches and significant financial loss.

Coating & Leak Repair of key cooling tower compoments

Basins

Fan blades

Fan shafts

Pans

Pipes

Seams

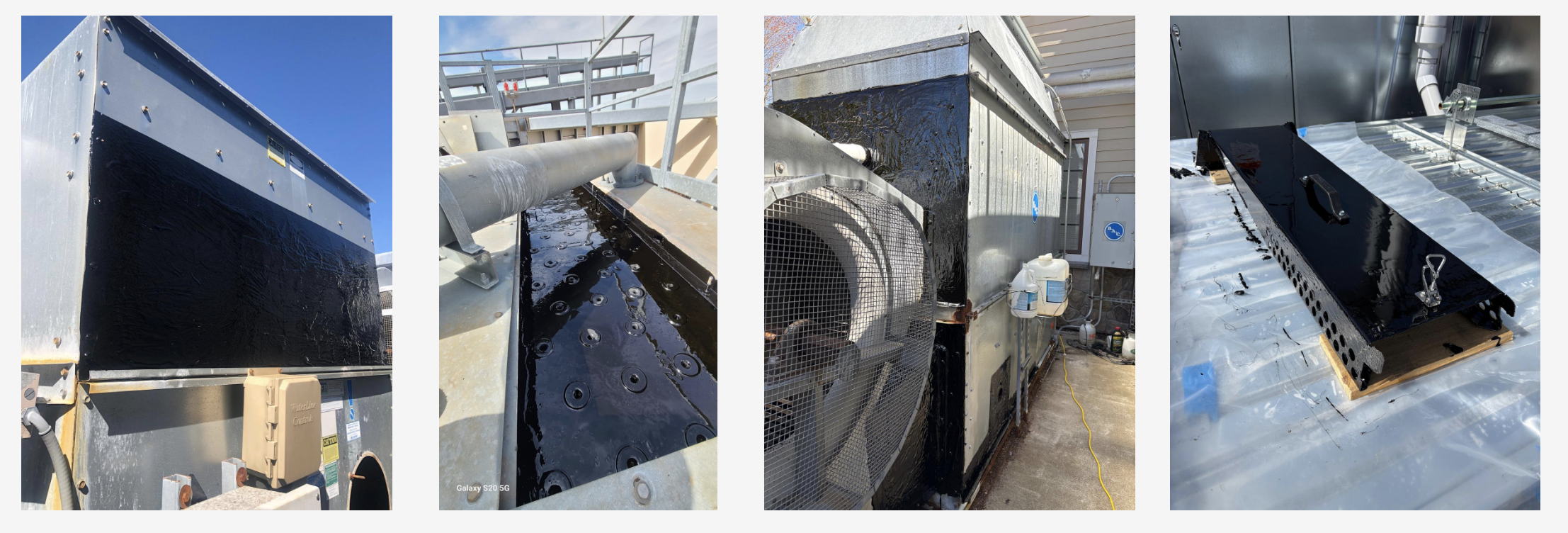

BMI’s Advanced Liquid Membrane Coating solution

BMI’s cooling tower coating process is designed for maximum protection and minimal disruption:

Comprehensive Preparation:

We assess all critical areas—sump, seams, wet deck, and sidewalls—preparing surfaces for optimal adhesion and repair.Liquid Membrane Application:

Our non-microbial liquid membrane system is expertly installed across the entire sump area (including seams for stainless sumps), topped over the wet deck, and extended up the sides. This seamless barrier prevents leaks, corrosion, and microbial growth.Rapid Turnaround:

For most tower sizes, your system is back online within 24 hours. Larger units may require up to three days, but we always work to minimize downtime and keep your operations running smoothly.Joint & Crack Repair:

We address any existing cracks or joint failures, ensuring a watertight, long-lasting result.

Recent Cooling Tower coating Projects:

The Results: Reliable, Efficient and Easy-to-Maintain Chillers

From rusty and clogged to renewed and protected, your chiller is returned to service with:

Improved cooling performance and energy efficiency

Reduced risk of leaks, corrosion, and refrigerant loss

Noticeably easier and faster cleaning times

Lower maintenance and repair costs

Peace of mind knowing your critical equipment is protected

Why Choose BMI Mechanical?

Long before we became New England’s trusted specialty coating and pump/motor specialists, we learned the value of showing up, listening closely, and delivering more than promised. Our team combines decades of hands-on experience with a solutions-driven, customer-first approach—delivering exceptional service to organizations across New England, especially the Greater Boston area.

With BMI, you get direct access to knowledgeable professionals, clear communication, and a hardworking crew focused on building long-term partnerships. We’re as committed to your facility’s success as you are.

Ready to protect your chiller and avoid costly breakdowns?

Contact BMI Mechanical today to schedule a chiller coating consultation or learn more about how our specialty coatings can safeguard your facility’s most important systems at 603-394-2188 or email us.